PONC [CIMT2025]: Beyond Equipment, Creating Greater Value

May 08, 2025

Beijing, April 21 – The global machine

tool industry converged on Beijing for CIMT2025 (19th China

International Machine Tool Exhibition), the world's largest machining

technology event spanning 310,000 sq.m.

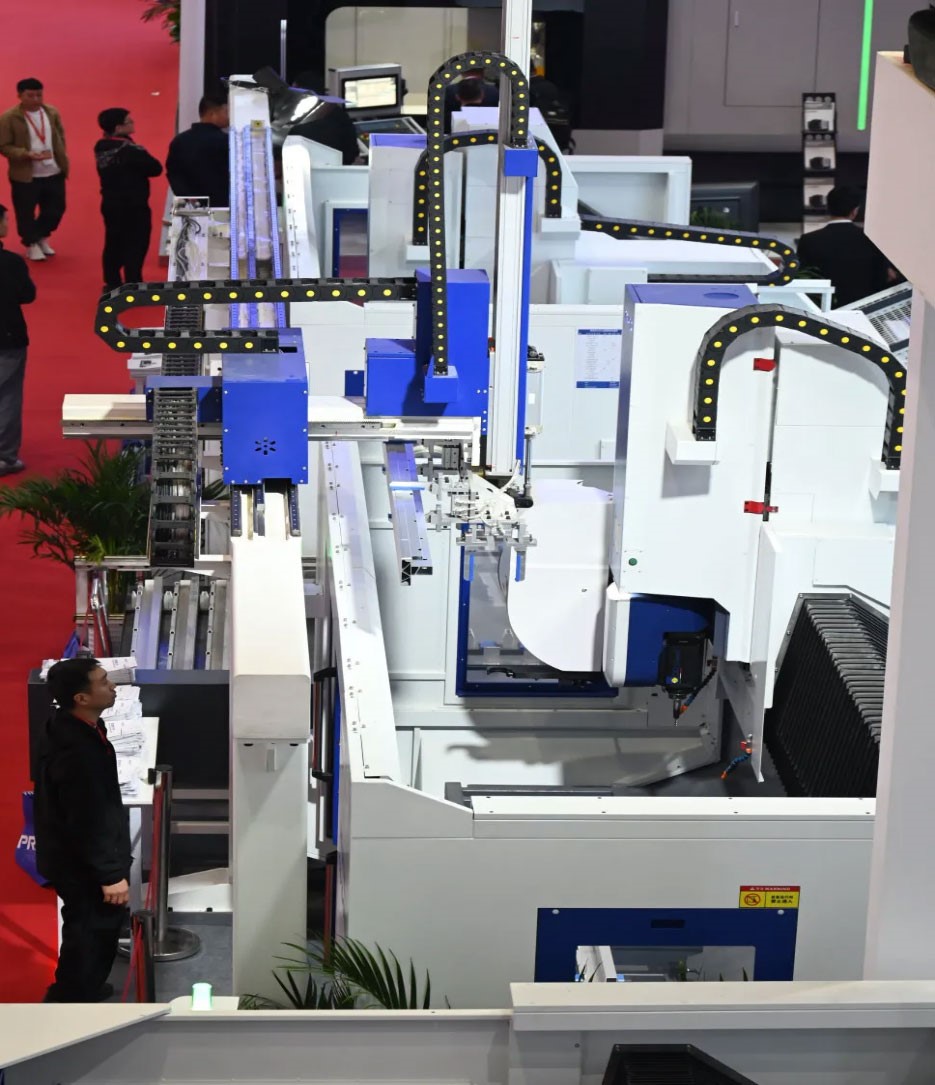

PONC's Spotlight at Hall E4-Booth A111

We showcased full-scenario industrial solutions, from multi-axis precision

equipment production lines.

With its vertically integrated industrial chain autonomy, PONC has launched two

groundbreaking machine tools that combine ISO certified performance parity with

disruptive cost-effectiveness, providing a dual competitive advantage and

reshaping the global manufacturing paradigm.

MACHINE PARAMETER

|

X-Axis

Travel |

4200/6200/8500mm |

|

Y/Z-Axis

Travel |

3900/800mm |

|

W-Axis

Travel |

1300mm |

|

Spindle

Speed |

6000rpm |

|

Spindle

Power |

17/25.5kW |

|

Output

Torque |

723/1085N·m |

The innovative moving beam gantry design breaks through the

height constraints of traditional fixed-beam systems, enabling precise

positioning and suspension at any coordinate point while seamlessly integrating

into 3-axis simultaneous machining operations. The W-axis comes standard with a

high-precision HEIDENHAIN linear encoder for closed-loop positioning

verification.

MACHINE PARAMETER

|

X-Axis

Travel |

3000mm |

|

Y-Axis

Travel |

2000mm |

|

Z-Axis

Travel |

1000mm |

|

Spindle

Power |

6000/18000rpm |

|

Spindle

Torque |

89/111N.m |

|

X/Y/Z

Rapid Speed |

60/60/30m/min |

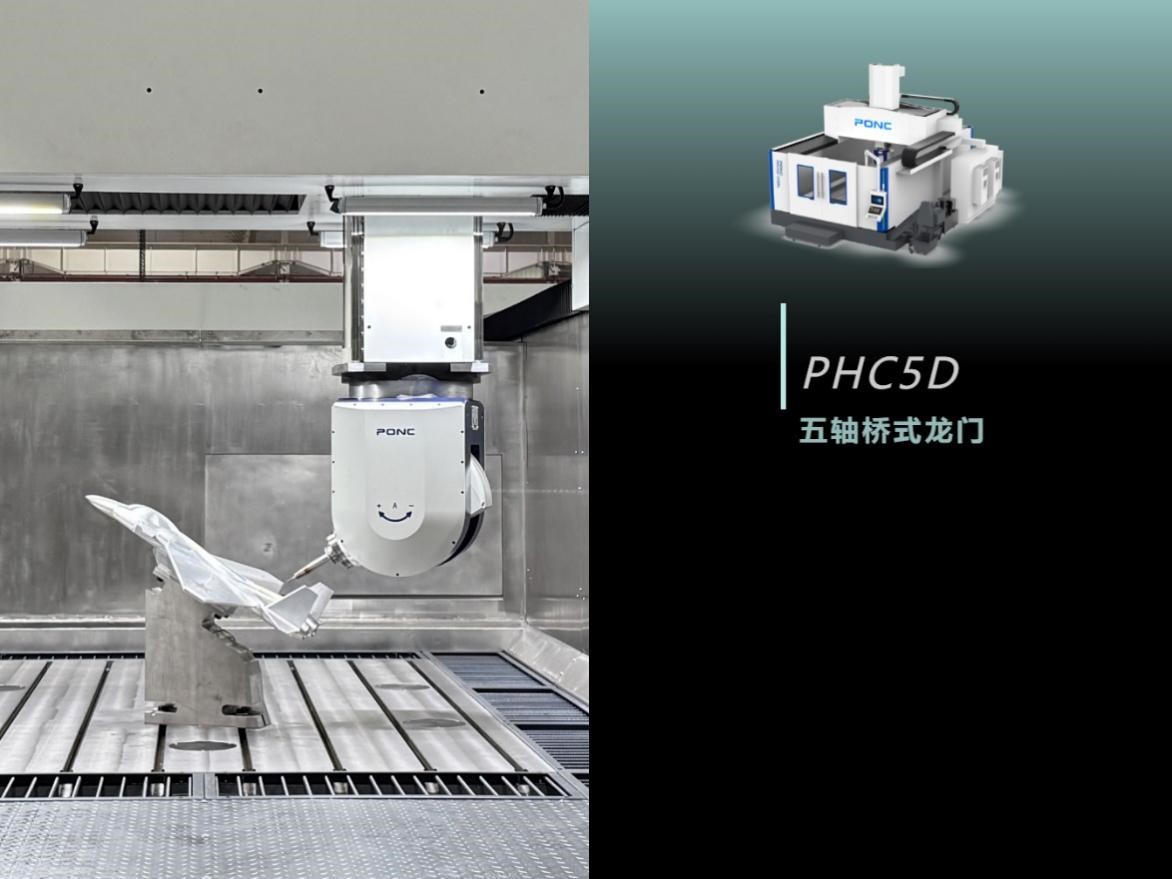

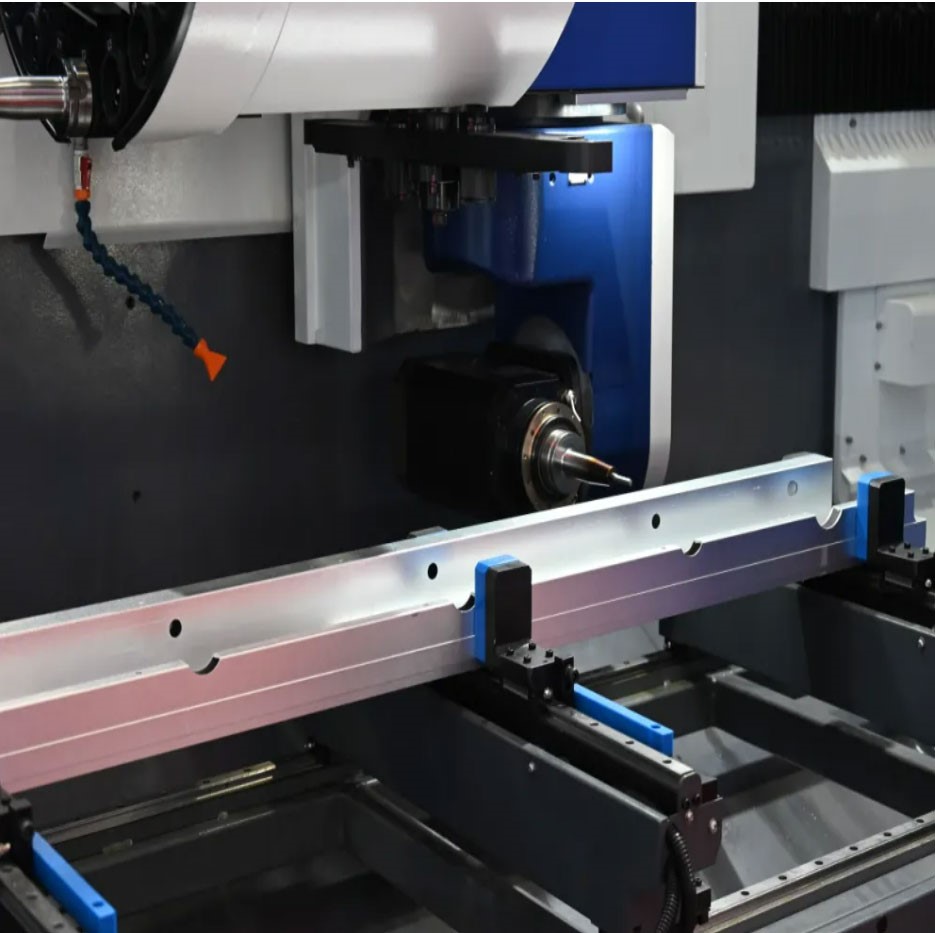

PHC5D

Bridge-Type 5-Axis Gantry Machining Center

Engineered specifically for the mold and die industries, this 5-axis

simultaneous machining system excels in processing medium-to-large steel

alloys, aluminum alloys, and composite materials, delivering unparalleled

precision for complex curved surfaces and multi-faceted geometries. PONC's two

heavy-duty gantry systems garnered critical acclaim from industry professionals

at CIMT2025.

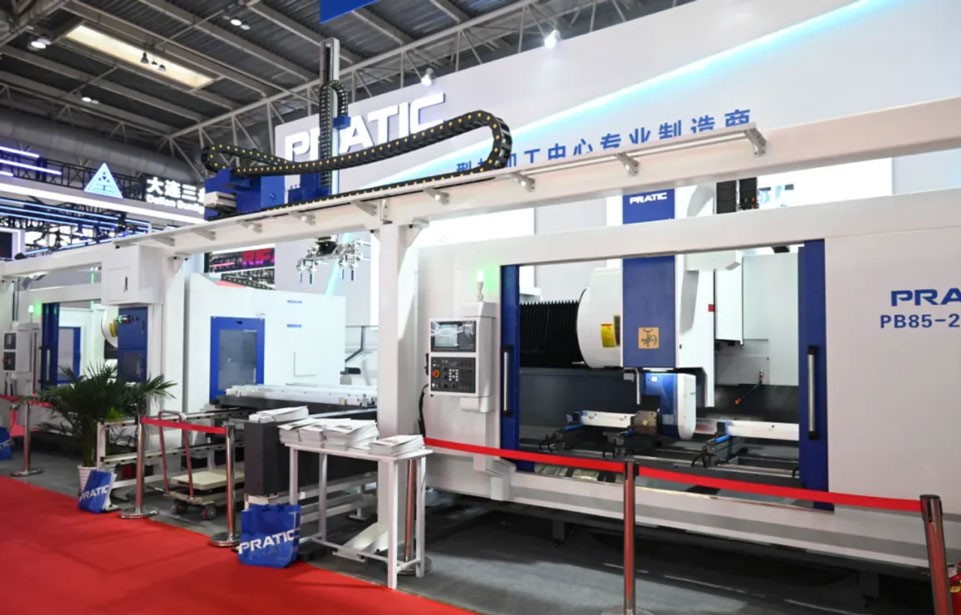

PONC also

carried another series of profile machining centers at the exhibition site, and

the truss-type automation line composed of PB series 3-axis equipment and 5-axis

equipment drew significant attention with its. PONC

engineering teams conducted daily all-day live demonstrations of equipment

operations during the exhibition period,

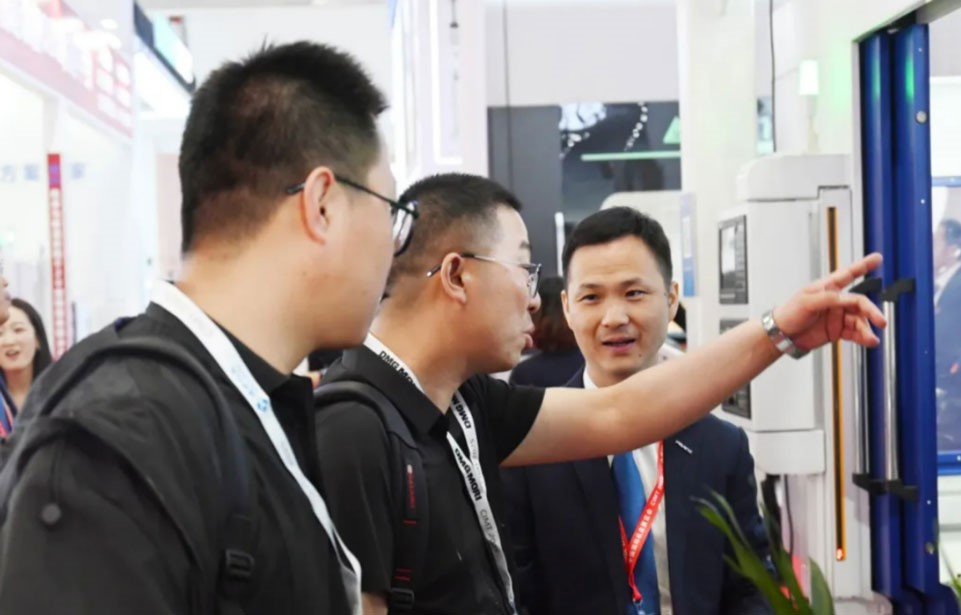

In the consultation area, the solution team conducts

technical discussions with clients worldwide, ranging from parameter analysis

to industry-specific application cases, offering tailored solutions to address

client pain points through one-on-one sessions.

Truss Manipulator-Based CNC Automation Solution

PONC leverages 17 years of expertise in CNC

profile machining to optimize robotic trajectory planning, ensuring precise match with

profile dimensions and machining cycles. This eliminates efficiency losses

caused by forced adaptation of generic automation solutions. The system is

particularly suited for high-volume, high-speed industries like automotive

manufacturing.

Cost advantage: Compared

to articulated robots with equivalent

payload capacities, truss manipulators offer significantly lower

upfront investment while maintaining comparable performance.

Space efficiency: Overhead-mounted

manipulators free up floor space, enhancing workshop layout flexibility and

operational efficiency.

Easy to adjust: flexible

switching between automation and manual operation modes, making it easier to

meet the handling requirements in case of abnormal situations. Providing more

diversified choices for enterprises in different production stages.

Intelligent Flexible Manufacturing:

Featuring universal fixtures, the system supports expandable material racks

along the length axis or integration of additional machining centers. It

enables flexible combination with 3-axis and 4-axis machine tools,

accommodating multi-category production including bumpers, luggage racks,

battery tray rods, and more.

Efficiency Revolution: Tray

alternating feeding/retrieval combined with PB equipment's 0.7g acceleration

enables non-stop high-speed machining. A fully robotic workflow—from loading and clamping to unloading—eliminates

intermediate steps and manual intervention, maximizing throughput."

Beyond Machinery, Delivering Value

Rooted in profound expertise in the CNC sector, PONC's turnkey engineering

capabilities align with the evolving demands for smart automation. We

understand our clients require not standalone machines, but future-ready solutions.

Through continuous technological convergence, PONC delivers comprehensive,

customized turnkey ecosystems dedicated to sustainable value creation.